Sludge Dryer Parts

- Description

- FAQ's

- Photos

- Videos

INFRARED GAS BURNERS AND HEATERS

M.W. Watermark™ can supply virtually any replacement part for your sludge dryer’s heating system, including infrared gas burners for all models of similar continuous dryers. Our Infrared Gas Burners are designed for efficient heating and long service life. We maintain a stock of other heating system parts like spark igniters, flame rods, thermocouples, air filters and many more for quick, easy replacement.

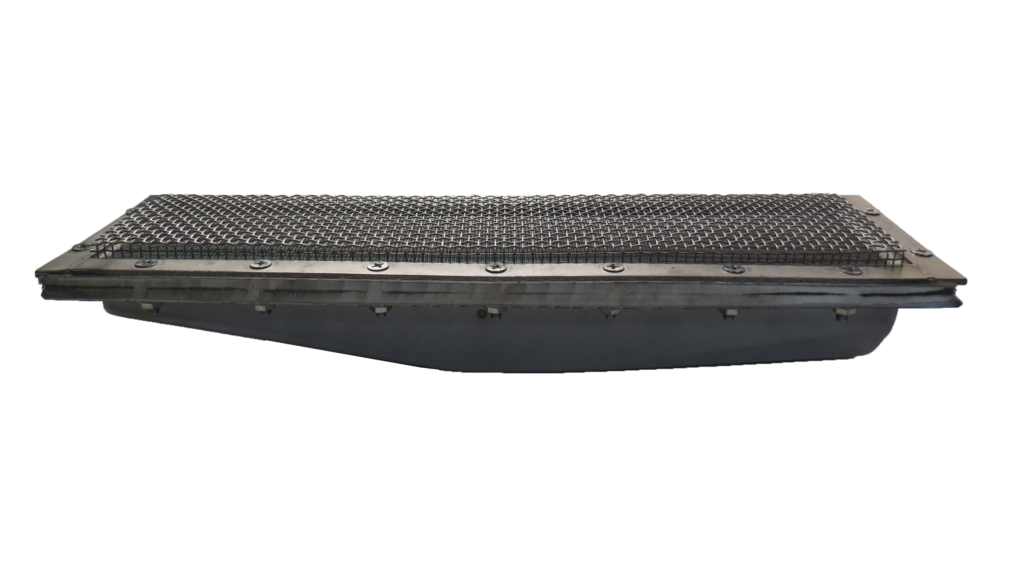

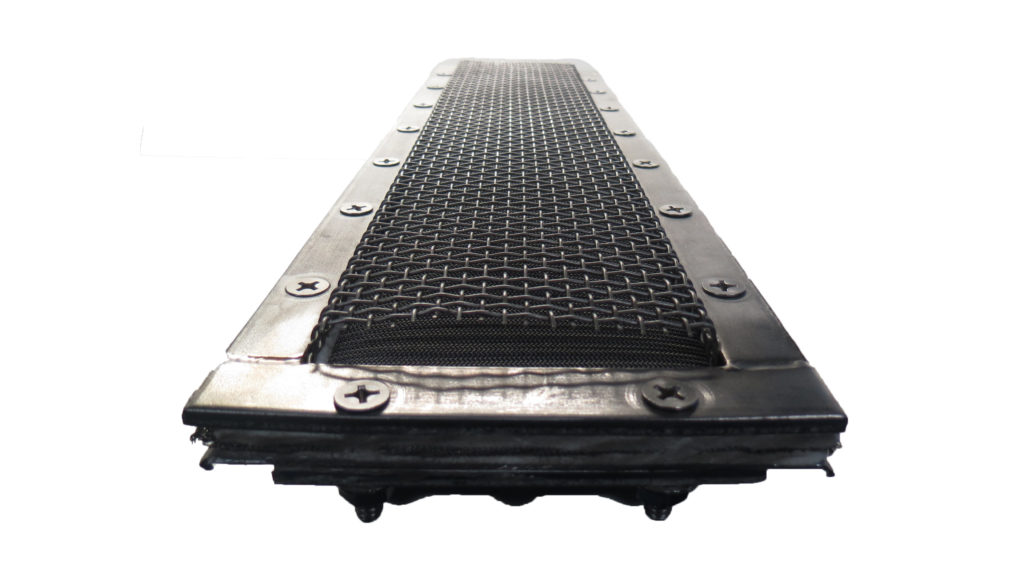

CONVEYOR BELTS, SPROCKETS, SHAFTS, HOPPER & EXTRUDER

M.W. Watermark™ carries a large stock of stainless steel conveyor belts as well as custom drive sprockets, gearboxes, bearings, and gears.

Replacement custom shafts, weldments and most any other fabricated parts for sludge dryers are available.

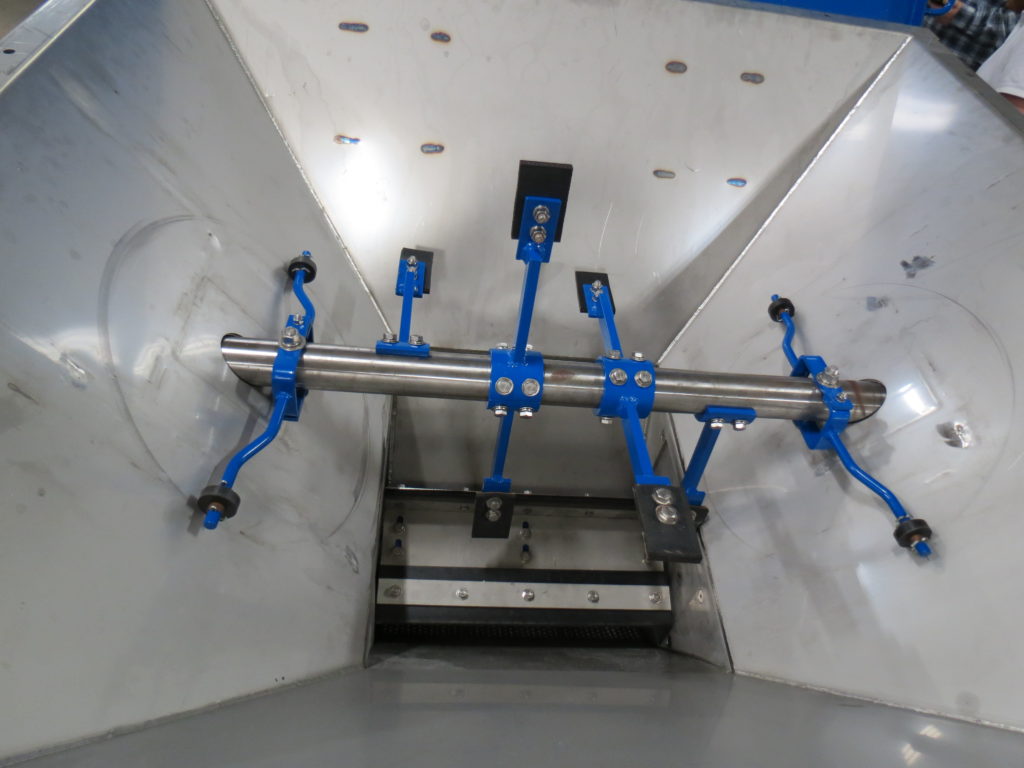

A complete line of extruder paddles, debridger paddles, hub arm plates (and backers) and wobble arm assemblies for almost any model of continuous sludge drying are kept in-stock.

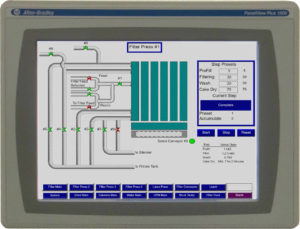

GAS TRAIN, SCRUBBER, CONTROLS, DISCHARGE BAGS

M.W. Watermark™ also carries original motors, DC motor control boards, timers, switches and electrical components.

Many sludge dryers use a wet scrubber to clean exhausting air. Our replacement parts to help keep you in compliance with air emission requirements.

For sludge dryers that discharge into sludge bags, we offer a complete line at competitive prices.

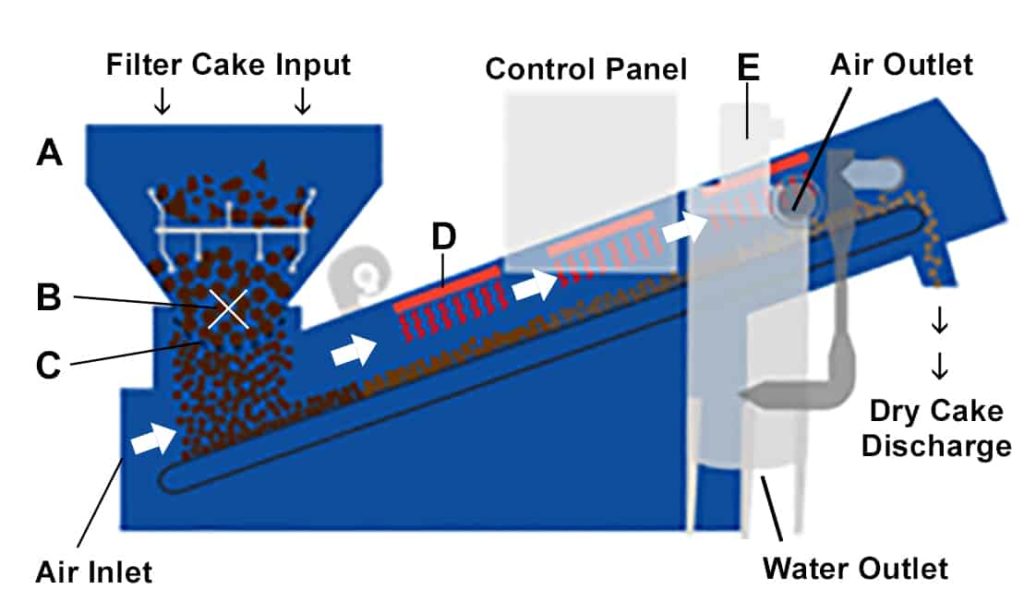

Q: How does a sludge dryer work?

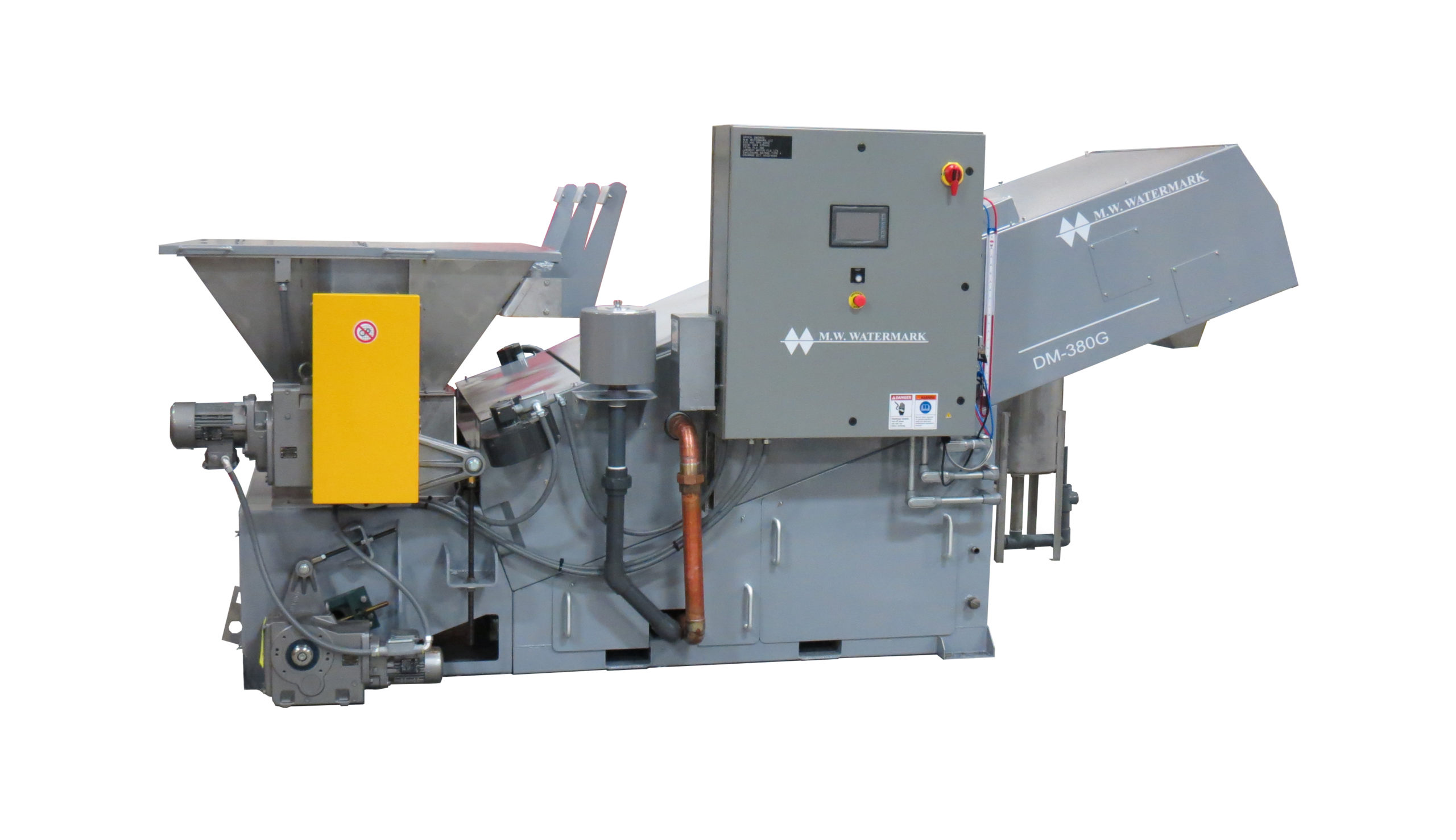

Our continuous sludge dryer is designed to be used in conjunction with a filter press, which dewaters metal hydroxide slurries from metal plating operations.

- The filter cake that is produced by the filter press is dumped into the sludge dryer receiving hopper (A).

- Wiper blades push the filter cake through a stainless-steel screen, decreasing the material’s size and shaping it for increased surface-area and efficient drying (B, C).

- Next, the noodle-shaped material falls onto a continuous stainless steel mesh belt, where it passes under a series of infrared heaters for drying (D).

- The heat is produced by natural or LP gas, while ambient air is drawn through the heat chamber by a fan mounted on the inlet of the wet scrubber (E).

- After significant reduction, the dry, granular material exits the dryer into a container for removal.

Q: What parts do you stock for sludge dryers?

M.W. Watermark™ can supply infrared gas burners and other heating system parts including conveyor belts, sprockets, shafts, hoppers & extruders, gas trains, scrubbers, controls, and discharge bags. We stock parts for most brands of continuous dryers!

For more info, check out our Sludge Dryers Parts Brochure.