Filter Press Plates

- Description

- FAQ's

- Photos

- Videos

Our Filter Press Plates

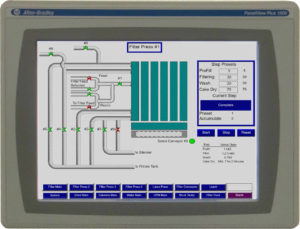

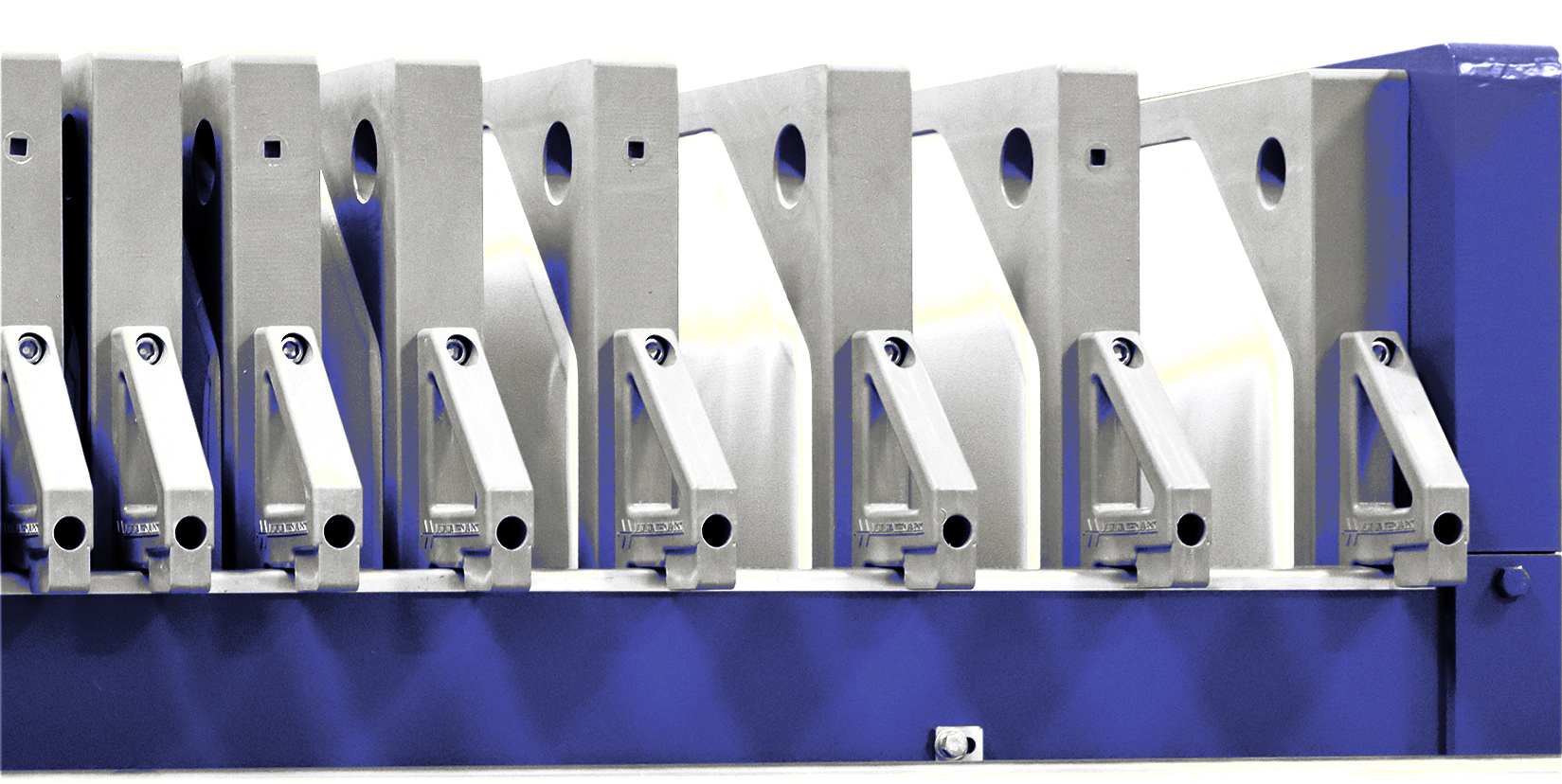

At M.W. Watermark, purchasing new filter plates couldn’t be easier. When it comes time to replace your filter plates, we understand you can’t afford much downtime – waiting weeks or months for a new set of plates to arrive for your filter press. Our filter plates have been selected to be compatible with most makes and models of filter presses. Our Sales and Service Team can recommend an appropriate filter plate based on your company’s equipment and needs.

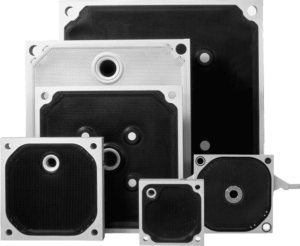

We offer the following types of high-density polypropylene filter press plates:

- Recessed Chamber

- CGR – Caulked, Gasketed, Recessed chamber (centerfeed or cornerfeed)

- Non-gasketed recessed chamber (centerfeed or cornerfeed)

- Plate and frame (cornerfeed)

- Membrane squeeze (centerfeed or cornerfeed)

Maintaining Filter Plates

We also offer parts for filter plates, including plate handles, plate plugs, cloth dog pegs and caps, and plate shifters. For these parts and other installation and maintenance tools such as gasketing materials, O-rings, dead blow hammers, wedges, handles, air hammers, plate and cloth installation tools or bulk bags, download our Aftermarket Accessories Sheet.

LARGE INVENTORY OF FILTER PRESS PLATES IN-STOCK FOR QUICK SHIPPING

At M.W. Watermark, purchasing new filter plates couldn’t be easier. When it comes time to replace your filter plates, we understand you can’t afford much downtime – waiting weeks or months for a new set of plates to arrive for your filter press. That’s why we stock an extensive inventory of high-density polypropylene filter plates that are compatible with many makes and models of filter presses

Large Inventory of Filter Plates

Need Filter Cloths to Go with Your Filter Plates?

M.W. Watermark also provides filter cloths for virtually all makes and models of filter presses. Filter cloths can be cut and sewn to the specifications of your filter press.

All cloths are made right here in the U.S.A. in our facility in Holland, Michigan, utilizing two laser cutting tables. Using lasers to cut cloth enables us to provide consistent, high-quality cloths with lower pricing, while at the same time providing faster turnaround on custom requests.

CONTACT US TODAY!

When your company is in need of new filter plates, the experts at M.W. Watermark provide the highest quality products and the fastest turnaround time. To learn more about how your company can utilize our products and services, call us at (616) 399-8850 or fill out our contact form and a service representative will contact you shortly.

Q: What are the advantages of recessed chamber filter presses and plates?

Check out our Guide to Recessed Chamber Filter Presses and Filter Plates

Q: What is a backup filter plate?

Check out our Backup Filter Plate Page for more information about them and why you would use one.

Q: What does it mean to sequence filter plates?

Check out our Filter Plate Sequencing Page for more information about how and why you should sequence your filter plates.

Q: How do you install filter plate gaskets?

Our Filter Plate Gasket Installation Guide is full of useful information about filter plate gaskets.

Q: What are the differences between the three types of filter plates?

Our Types of Filter Plates page details the differences between plate types.

Learn more about when to best utilize a membrane squeeze filter press.

Q: How can I tell if my filter plates are worn or damaged?

Our Guide for Evaluating Worn or Damages Filter Plates will help you determine if it’s time to consider replacements.

Videos Coming Soon!