Filter Press

Liquid-Solid Separation

M.W. Watermark™ filter presses are used for process-liquid, water, and wastewater in a variety of different industries and applications. Anywhere a company needs to separate solids from liquid, we can help.

- Description

- FAQ's

- Photos

- Videos

SIZES AND TYPES OF FILTER PRESSES

We offer a broad array of filter press sizes to meet your needs. From our large 2000mm/600 cuft (17000L) down to our 250mm/.02 cuft (5.5L) portable pilot filter press. Our selection provides the right size filter press for your specific project.

Try our sizing calculator to help determine the capacity required for your application.

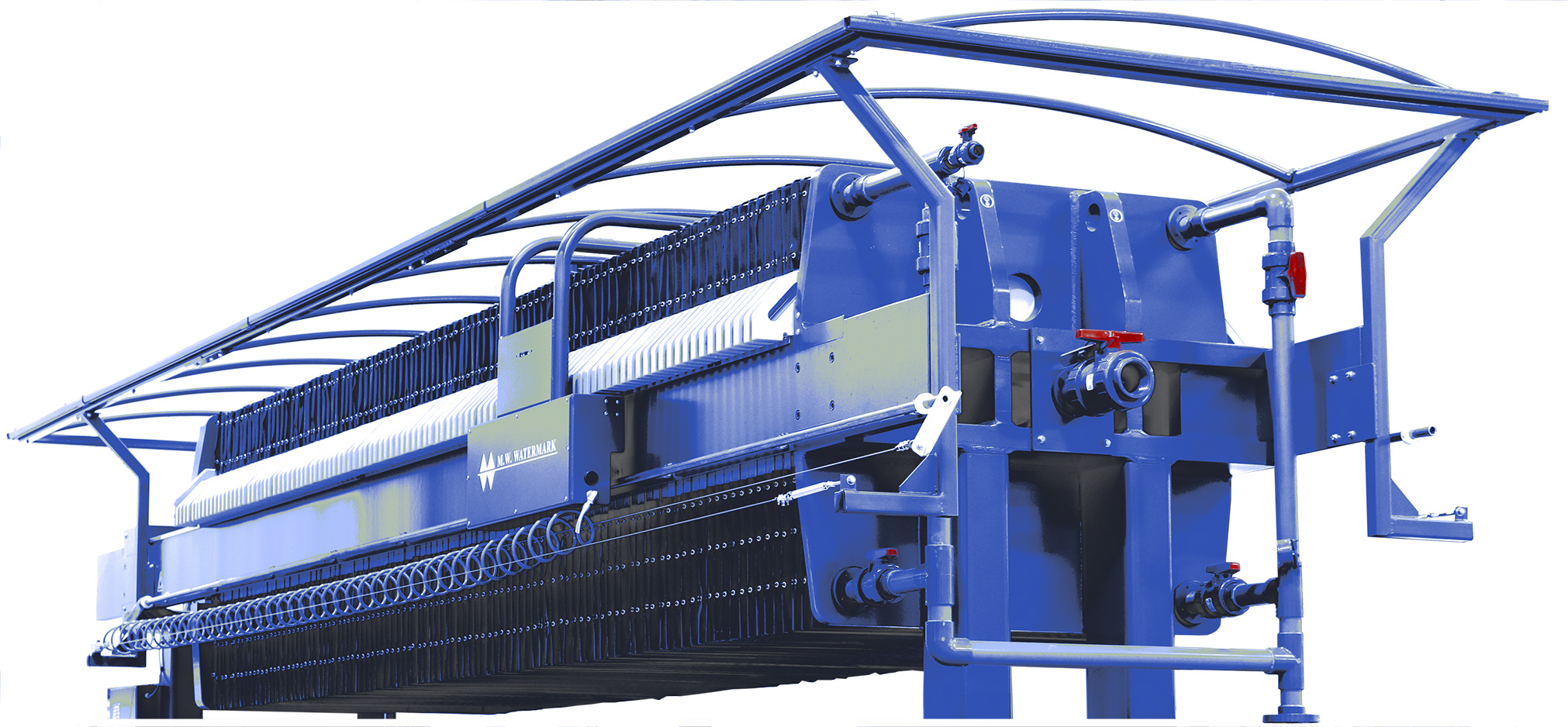

2000mm Filter Press

Options Shown:

Overhead Plate Suspension

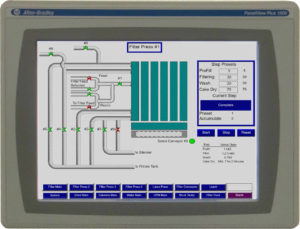

Full Automation Control System

Automatic Plate Shift with Cloth Washer

Light Curtains

Automated Valves

1500mm x 2000mm

Filter Press

Options Shown:

Automatic Drip Trays

Double Air Blowdown

Even Fill Manifold

1500mm Filter Press

Options Shown:

Custom Coating

Automatic Plate Shifter

Full Automation Control System

1200mm Filter Press

Options Shown:

Custom Coating

Semi-Automatic Plate Shifter

Automatic Drip Trays

Core Blow Manifold

Automated Valves

1000mm Filter Press

Options Shown:

Automatic Plate Shifter with Cloth Washer

Electric Hydraulics

Automatic Drip Trays

Automated Valves

800mm Filter Press

Options Shown:

Semi-Automatic Plate Shifter

Air/Oil Hydraulics

630mm Filter Press

Options Shown:

Air/Oil Hydraulics

Optional Expansion Piece

470mm Filter Press

Options Shown:

Air-Operated Feed Pump

Filter Cake Hopper

320mm Filter Press

250mm Filter Press

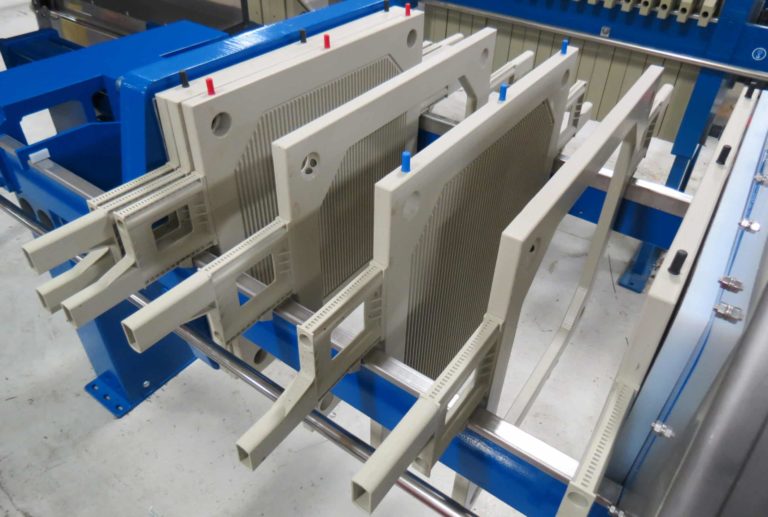

In addition to manufacturing many sizes of filter presses, we also build presses to utilize multiple types of filter plates, including recessed chamber, plate and frame and membrane squeeze.

PARTS AND ACCESSORIES FOR YOUR FILTER PRESS

We also carry a wide selection of filter press parts and accessories including elevated platforms, chutes, self-dumping cake hoppers, plate shifters, hydraulic systems, valve manifolds, and more.

NEW AND REBUILT EQUIPMENT

In addition to manufacturing our own filter presses and parts in-house, we also take great pride in our ability to rebuild pre-owned equipment. Our talented team has experience with top brands in the industry including Siemens, US Filter, JWI, Lanco, Perrin, Edwards & Jones, Pac Press, and others. We can repair or rebuild your current equipment and advise you on additional products to make your system run as smoothly as possible.

Learn more our Pro-X Series filter press specially engineered for the food industry, beverage industry, pharmaceuticals, and other sanitary applications.

WHY CHOOSE M.W. WATERMARK?

M.W. Watermark is committed to providing industry leading equipment, service, and direction. We operate in a family-oriented environment with loyal employees who have been with us for several years. Our staff works hard to make sure we deliver the best. We are passionate about caring for the world’s water supply.

Our passion spills over to our commitment to being an environmentally conscious company who make high-quality products in the United States. Our Quick-Ship program allows us to deliver in-stock equipment with short lead times, and items not in-stock can be procured with little delay. We’re friendly and easy to contact by phone or email.

Click Here to Download Our Filter Press Product Guide

Need accessories for your filter press, including spatulas, cloth installation tools or bulk bags?

Download our Aftermarket Accessories Sheet.

Contact us to see if we have the filter press you need in-stock. If not, we can also build custom equipment based on your specifications. At M.W. Watermark, we are committed to our customers and our planet. Call us today to learn more.

Q: What is a filter press?

Check out WHAT IS A FILTER PRESS? We’ll also give you some other information on filter presses. Our Sales and Service Team is looking forward to answering any other questions you might have.

Q: What size filter press do I need?

Because filter presses are used across so many applications, there is no “one size fits all” when it comes to determining filter press sizing requirements. See HOW TO DETERMINE THE SIZE OF FILTER PRESS

Q: What is a plate and frame filter press and what is a recessed chamber filter press?

To learn more about the differences, check out PLATE AND FRAME FILTER PRESS VS. RECESSED CHAMBER FILTER PRESS

Q: What is the difference between a sidebar filter press and an overhead filter press?

M.W. Watermark manufactures two different styles of filter press frames: sidebar and overhead. To learn more, see SIDEBAR FILTER PRESS VS. OVERHEAD FILTER PRESS

Q: Does my filter press need service?

Check out SIGNS YOUR FILTER PRESS MAY NEED SERVICE. Ensuring your filter press receives the service it needs is essential in maximizing its life and streamlining your operation’s filtration efficiency.

Q: What are some of the common filtering issues?

Check out COMMON FILTER PRESS “FILTERING” ISSUES AND SOLUTIONS for more info.

Q: How do membrane squeeze filter presses work?

There are three types of filter plates used in conjunction with filter presses. They include recessed chamber, plate & frame and membrane squeeze plates. To learn more about membrane squeeze filter presses, see MEMBRANE SQUEEZE FILTER PRESSES AND FILTER PLATES: HOW THEY WORK AND WHEN BEST TO UTILIZE

Q: What is filter press precoat?

See PRECOAT: WHAT IT IS AND HOW TO APPLY IN A FILTER PRESS to learn more.

Q: How do you open and close a manual filter press?

Click on HOW TO CLOSE/OPEN A MANUAL FILTER PRESS for a video and detailed instructions.

Q: How can I increase my filter press capacity?

Your filter press may have been designed with an expansion piece, also known as a distance piece. If you’re ready to increase its capacity and add more filter plates, the expansion piece must be removed. For instructions how, see EXPAND MY FILTER PRESS for instructions how.