Standard and Custom-Made Filter Cloths

• Standard Cloths, Large Inventory In-Stock

• Custom Cloths, Per Customer Specification

• Quick Turnaround

• High Quality

• Direct Ship

• Perfect Fit

- Description

- FAQ's

- Photos

- Videos

This video illustrates MW Watermark’s filter cloth manufacturing processes.

MW Watermark Filter Cloth Installation Video

INFORMATION ABOUT FILTER CLOTHS

When separating solids from liquids using a filter press, the very foundation lies within the filter cloth. This is the front line of the dewatering process. The cloth will separate the fine particles from the water or other type of liquid in your application, forming a filter cake. This is the deposit of solid materials left behind after the filtering process.

We offer stock cloths in various sizes for quick shipping. We can also customize cloths to match the specifications of your filter press, providing for a perfect fit. Our fabric department maintains a large inventory of rolled goods with a wide variety of filtration characteristics allowing us to customize cloths for almost any filter press application.

FILTER CLOTH SPECIFICATION

We place the emphasis on value, which is why we offer products that keep costs down. Our products are of the highest quality, and we offer filter cloths made of the following materials: Polypropylene, Polyester, Cotton, Nylon, Polyester and Felt.

Our sales team will offer recommendations of which product to use for your specific needs, considering the required filtrate clarity, flow rate, and cake release of your project.

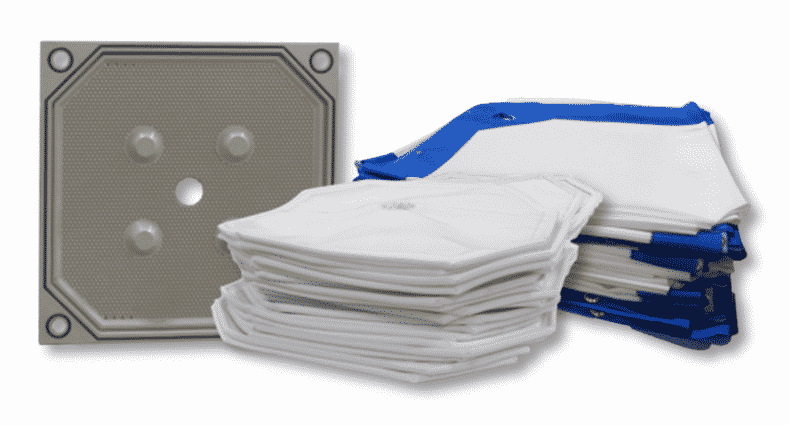

We offer filter cloths for the following types of plates: Gasketed, Non-Gasketed, Centerfeed, Cornerfeed, Membrane, and Plate and Frame.

Q: How do you select the proper filter cloth?

Filter cloths come in many shapes, sizes, and fabric types. Filtration results can vary depending on the raw materials used and the fiber types, weaves and finishing of the type of cloth being used. Matching the most appropriate filter cloths for a given project requires knowledge of the design needed as well as the process application. To learn more, see HOW TO SELECT THE PROPER FILTER CLOTH FOR YOUR APPLICATION.

Q: How do I know when to replace my filter cloths?

Filter cloths need replacement when your filter press is no longer forming a solid cake. If you see low pressure despite cleaning, then it is likely that the permeability is too low. After many uses, the particles get lodged so deep in the fabric that neither cleaning nor even chemical washing is worth the time.

If you see impurities in the output and insufficient caking, then your fabric is likely too porous as a result of stretching or warping in the weave, and you should begin to look for a replacement. Remember, because you put these parts through the ringer, they’ll need replacing from time to time.

Q: How long will my filter cloths last?

Filter cloth life can be shortened by certain chemicals in the slurry, mechanical wear, abrasion and blinding. Regular cleaning of the filter cloths and preventative measures can help your filter presses to operate at optimal performance levels.

To learn more, see HOW TO MAXIMIZE THE LIFE OF YOUR FILTER CLOTHS

Q: How can I order filter cloths?

M.W. Watermark™ understands that when your filter cloths need to be replaced, every day that you have to wait for new cloths is costing you. That’s why we make ordering filter cloths as easy and as streamlined as possible, allowing you to get your operation back up and running quickly, with minimal downtime. For more. See TEMPLATE FORMS MAKE ORDERING FILTER CLOTHS QUICK AND EASY

Q: What are head cloths, intermediate cloths, and tail cloths?

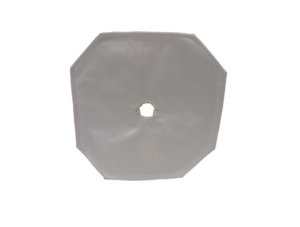

Head Cloth

Usually a single-panel cloth with a center hole, attached to the head filter plate. Other configurations include drape-over and barrel-neck cloths. (Gasketed cloth shown). Learn more on how to install the head cloth.

Learn more on how to install the head cloth

Intermediate Cloths

These are the filter cloths that constitute the majority of the cloths in the filter press and are attached to the intermediate filter plates between the head plate and the tail plate. (Gasketed cloth shown).

Tail Cloth

This is the last cloth in the plate stack – a single-panel cloth without a hole, attached to the tail filter plate, may be a drape-over cloth design. (Gasketed cloth shown).

Q: What does cloth blinding mean?

When a cloth’s porosity is hindered, and the cloth no longer allows the filtrate to flow.

Q: What is the difference between CGR and NG filter plates?

CGR vs. NG

“CGR” is an acronym for “Caulked, Gasketed, Recessed chamber.” CGR plates should provide a virtually leak-proof filter press. Cloths for these plates are octagon shaped, with a caulking rope or cord sewn into the edge of the cloth. “NG” means “Non-Gasketed.” The NG cloth is faster and simpler to install, though the tradeoff is that occasionally some dripping can happen when using NG cloths.

Q: How do you install filter cloths?

There are two main types of filter plates found in filter presses that require filter cloths to be attached: CGR (Caulked, Gasketed, Recessed Chamber) and NG (Non-Gasketed). For more info, including CGR toolkit, see options for filter cloth attachment.