As a leader in the wastewater treatment equipment industry, it’s important to M.W. Watermark that we provide our customers with options to suit their unique needs. Because of that, we manufacture two different styles of filter press frames: sidebar and overhead. Our Capital Sales Team can help you choose which frame type would be the best fit for your application, as well as size your press appropriately, but here’s a guide to the difference between the two styles.

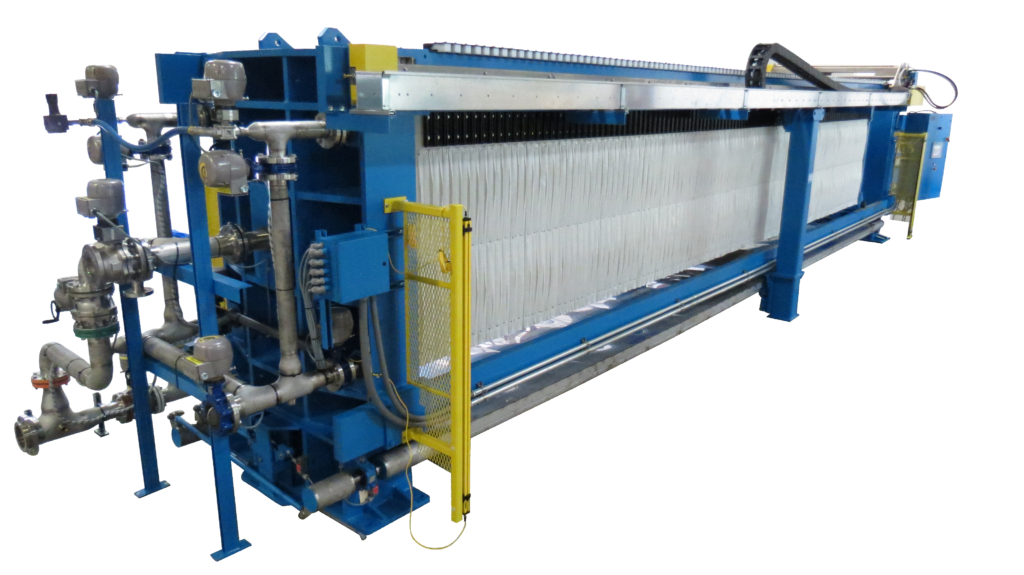

SIDEBAR-STYLE FILTER PRESS

It’s worth noting that the sidebar filter press is by far the most common style.

- The filter plates are suspended by handles that rest on the sidebar.

- The hydraulic cylinder keeps the filter pack closed during the filtration cycle.

- Sidebar presses can be sized from 250mm to 2000mm (.01 – 600 cubic feet).

- M.W. Watermark presses come outfitted with a 304 stainless steel sidebar wear cap

- Sidebar filter presses are available 100 psi and 225 psi.

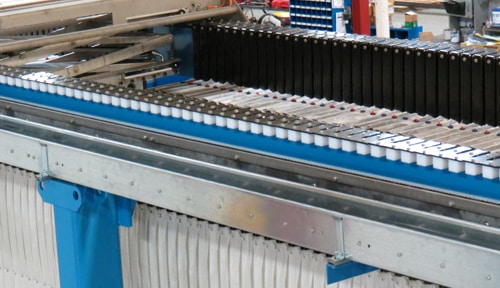

OVERHEAD-STYLE FILTER PRESS

- The filter plates suspended from above, making the filter plate stack easily accessible to the operator.

- Overhead style presses are sized 1200mm to 2000m (100 – 600 cubic feet)

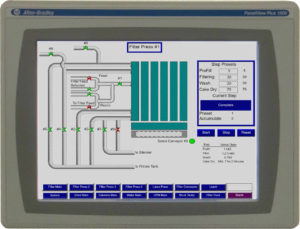

- These presses are typically fully automated.

- Compression close is standard; tension close may be used.